Secondary Clutch

The secondary clutch, or as some call it, the driven clutch, is mounted to the splined input shaft of the transmission and is connected to the primary clutch with a belt that wraps around both clutches. It responds to two different forces: the force that the belt puts on it from the primary clutch and the force that the shaft puts on it from the transmission.

The secondary clutch, or as some call it, the driven clutch, is mounted to the splined input shaft of the transmission and is connected to the primary clutch with a belt that wraps around both clutches. It responds to two different forces: the force that the belt puts on it from the primary clutch and the force that the shaft puts on it from the transmission.

The secondary clutch is a much larger diameter than the primary clutch and the belt wraps around the outside of the two sheaves, again one being fixed and one being movable. When the primary clutch begins to shift it forces the belt higher in the primary clutch. This causes the belt to get tighter and tries to pull the belt down in the secondary, forcing the two sheaves apart or as some would say, forcing the clutch to shift. Because the belt has such a large diameter to pull around, it starts in a really low gear with a lot of leverage to turn the clutch, which in turn rotates the shaft and makes the machine move.

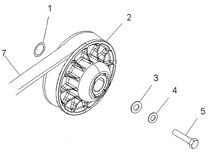

As the clutch continues to shift, it progressively turns around a smaller diameter. The smaller the diameter, the higher the gear ratio, which makes the machine travel faster. Like the primary, there are parts inside the secondary clutch to control how fast it shifts. Here is a break down: (see figure B)

As the clutch continues to shift, it progressively turns around a smaller diameter. The smaller the diameter, the higher the gear ratio, which makes the machine travel faster. Like the primary, there are parts inside the secondary clutch to control how fast it shifts. Here is a break down: (see figure B)

The fixed sheave is connected to the shaft that the movable sheave slides on. The roller assembly (8, 9, 13, 14) slides onto the splined shaft and is held in place with a snap ring (12). A spring (15) is installed between the movable sheave and the roller assembly. Without it, down pressure from the belt would try to open the clutch too fast. The helix (10), or cam as some call it, is bolted to the movable sheave and rides against the rollers mounted to the roller assembly. As the movable sheave begins to shift, the pressure generated from the helix riding on the roller provides resistance against the shift. Because the part of the helix that rides against the roller is cut at an angle, the angle can be changed to allow more or less resistance to the shift.

Polaris changed to a different style clutch for 2010 and 2011. (see figure C) It still basically functions the same as the 2008-2009 style but uses fewer parts. The helix and movable sheave are cast as one unit meaning the helix is not removable. They also moved the roller assembly to the inside of the stationary sheave and the spring and snap ring to the outside of the movable sheave. The downside to this is that you can't tune the clutch by switching to a different angle helix because the helix is not removable. For this, you will need to purchase an aftermarket clutch that uses a removable helix like the one SLP uses and sells.

Parts

Now that you understand the names and locations of the individual parts, it is critical to know which ones are important to maximizing the performance of your clutches. There are four main tuning parts that allow the user to calibrate to his or her performance criteria: the primary spring, the primary weights, the secondary spring and the secondary helix. For each basic part there are many different versions or options of that basic part to choose from. At first all these parts can be confusing and overwhelming mainly because the user just doesn't understand the small differences between them and how that difference will affect the calibration of the clutches and performance of the machine. Let's clarify these differences.

Primary Weights